Work Centers & Routings

Work Centers

Work centers represent units of production, capable of doing material transformation operations. You can distinguish two types of work centers: machines and human resources.

Work centers are units of production consisting of one or several people and/or machines that can be considered as a unit for the purpose of forecasting capacity and planning.

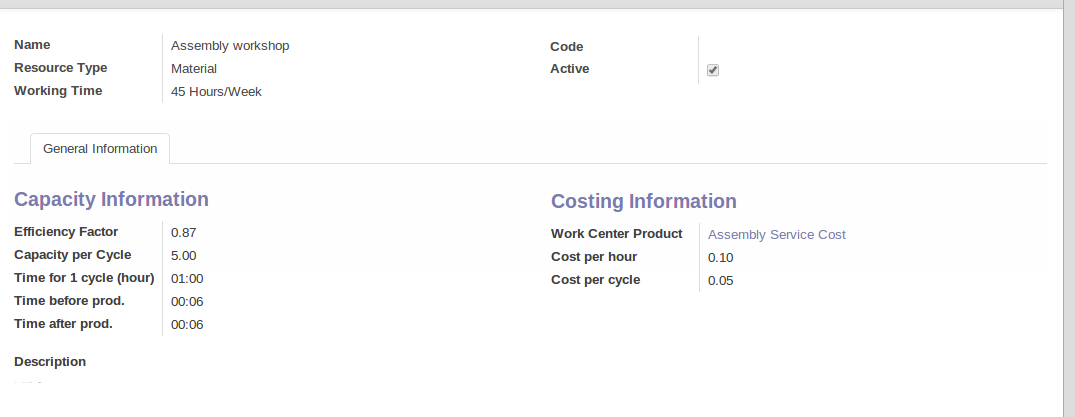

Use the menu Manufacturing > Configuration > Work Centers to define a new work center. You get a form as shown in the figure Defining a Work Center.

Defining a Work Center

A work center should have a name. You then assign a type: Material or Human, a code and the operating hours, i.e. Working Period. The Working Time(s) can be defined through the menu Manufacturing > Configuration > Resources > Working Time. The figure Defining a Work Center represents the hours from Monday to Friday, from 08:00 to 18:00 with a break of an hour from 12:00.

You can also add a description of the work center and its operations.

Once the work center is defined, you should enter data about its production capacity. Depending on whether you have a machine or a person, a work center will be defined in cycles or hours. If it represents a set of machines and people you can use cycles and hours at the same time.

A cycle corresponds to the time required to carry out an assembly operation. The user is free to determine which is the reference operation for a given work center. It should be represented by the cost and elapsed manufacturing time.

For example, for a printing work center, a cycle might be the printing of 1 page or of 1000 pages depending on the printer.

To define the capacity properly, it is necessary to know, for each work center, what will be the reference operation which determines the cycle. You can then define the data relative to the capacity.

Capacity per Cycle (CA): the number of operations that can be done in parallel during a cycle. Generally, the number defines the number of identical machines or people defined by the work center.

Time for 1 cycle (hour) (TC): the duration in hours for one cycle or the operations defined by a cycle.

Time before production (TS): the time in hours required to initialize production operations. Generally, this represents the machine setup time.

Time after production (TN): the delay in hours after the end of a production operation. Generally, this represents the cleaning time necessary after an operation.

Efficiency factor (ET): the factor that is applied to the TC, TS and TN times to determine the real production time. This factor enables you to readjust the different times progressively and as a measure of machine utilization. You cannot re-adjust the other times, because generally they are taken from the machine's data sheet. By default, the efficiency is set to 1, representing a load of 100%. When you set the efficiency to 2 (i.e. 200%), the load will be 50%.

The total time for carrying out X operations is then given by the following formula:

((X / CA) * TC + TS + TN ) * ET

In this formula the result of the division is rounded upwards. Then, if the capacity per cycle is 6, it takes 3 cycles to realize 15 operations (15/6 = 2.5, rounded upwards = 3).

If you leave the different fields empty, it will not have any effect on the analytic accounts.

Routings

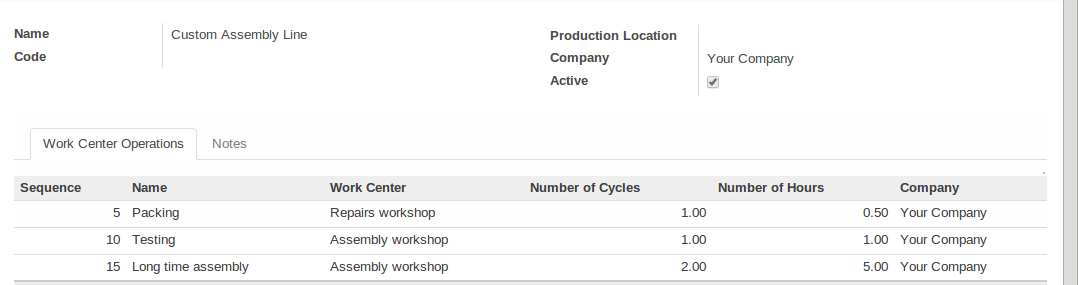

Routings define the manufacturing operations to be done in work centers to produce a certain product. A routing is usually attached to bills of materials, which will define the assembly of products required for manufacturing or to produce finished products.

A routing can be defined directly in a bill of materials or through the menu Manufacturing > Products > Routings. A routing has a name, and a code. You can also add a description. Later in this chapter you will see that a routing can also be associated with a stock location. This enables you to indicate where an assembly takes place.

Defining a routing with Three Operations

You will see further on in this chapter that you can also link a routing to a stock location for the customer or the supplier. You can use this functionality when you have subcontracted the assembly of a product to a supplier, for instance.

In the routing, you have to enter the list of operations that has to be executed. Each operation has to be done at a specific work center and includes a number of hours and/or cycles.

It is possible to define routing on several levels to support multi-level bills of materials. You can select the routing on each level of a bill of materials (BoM in a BoM can have a different routing). The levels are then linked to hierarchies of bills of materials.