Matching Sales Orders and Bills of Materials

In Odoo ERPOnline, you can define several bills of materials for the same product. In fact, you can have several manufacturing methods or several approved raw materials for a given product. You will see in the following section that the manufacturing procedure (the routing) is attached to the Bill of Materials, so the choice of bill of materials implicitly includes the operations to make it.

Once several bills of materials have been defined for a particular product, you need to have a system to enable Odoo ERPOnline to select one of them for use. By default, the bill of materials with the lowest sequence number is selected by the system.

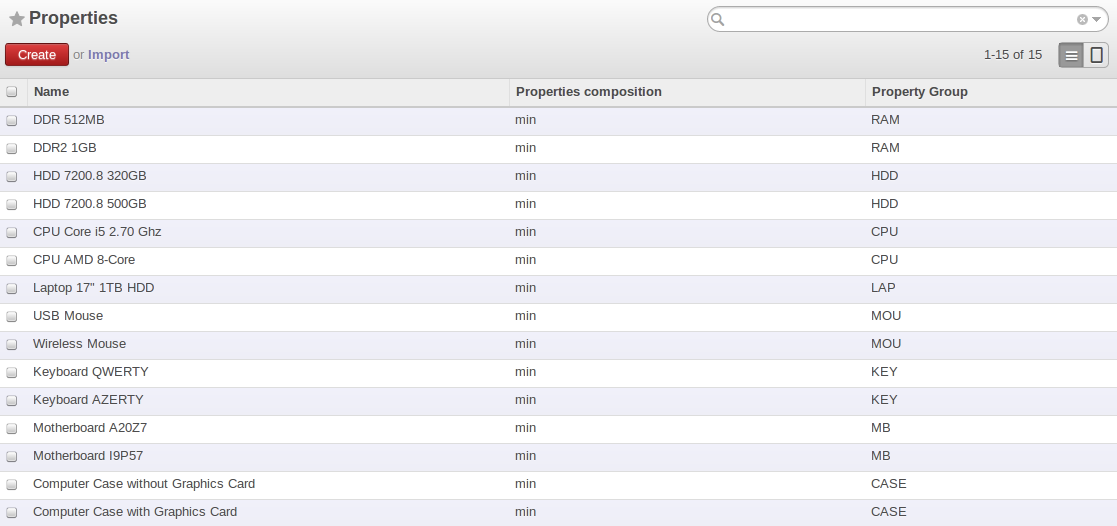

To gain more control over the process during selling or procuring, you can use Properties. The menu Manufacturing > Configuration > Properties enables you to define properties, which can be set up arbitrarily to help you select a bill of materials when you have a choice of BoMs.

Properties is a concept that enables the selection of a method to manufacture a product. Properties define a common language between salespeople and technical people, letting the salespeople have an influence on the manufacturing of the products using non-technical language and the choices decided on by the technicians who define Bills of Materials.

For example, you can define the following property groups and properties:

| Property Group | Property |

|---|---|

|

Warranty |

3 years |

|

Warranty |

1 year |

|

Method of Manufacture |

Serial |

|

Method of Manufacture |

Batch |

Once the bills of materials have been defined, you could associate the corresponding properties with them. Then when the salesperson enters a sales order line, he can attach the properties required. If the product has to be manufactured, Odoo ERPOnline will automatically choose the bill of materials that matches the defined properties in the order most closely.

Note that the properties are only visible in the Bills of Materials and Sales Management if you have select option Allow several bill of materials per products using properties from menu Settings > Configuration > Manufacturing.

Properties in a Customer Order Line

As an example, take the manufacturing of the shelf presented above. You can imagine that the company has two methods of manufacturing for this cabinet:

- Manually: the staff assembles the shelves one by one and cuts the wood plank by plank. This approach is usually used to assemble prototypes. It gets you very rapid production, but at a high cost and only in small quantities.

- On a production line: the staff uses machines that are capable of cutting wood by bandsaw. This method is used for production runs of at least 50 items because the lead times using this method are quite lengthy. The delay to start the production is much longer, yet the cost per unit is considerably lower in this volume.

You define two bills of materials for the same cabinet. To distinguish between them, you will define two properties in the same group: manual assembly and production line assembly. In the quotation, the salesperson can set the method of manufacture he wants on each order line, depending on the quantities and the lead time requested by the customer.

In some software, you use the term substitute for this principle of configurable properties in a bill of materials.

By putting a bill of materials on its own line, you can also implement substitute products. You set the bill of materials to type Sets/Phantom to make the substitution transparent and to prevent Odoo ERPOnline from proposing an intermediate production order.